In Baton Rouge, the industrial and commercial sectors have seen rapid growth over the years. This expansion has led to an increasing demand for custom metalwork and specialized fabrication solutions. Among these, precision coil bending has emerged as a critical service for industries requiring accuracy, durability, and innovation. Here’s why businesses in Baton Rouge consistently rely on our expertise in this field.

The Art and Science of Precision Coil Bending

Precision coil bending is not merely a technical process—it’s a fusion of art and science. This method involves manipulating metal tubing or piping into specific coil shapes, which are often integral to heating, cooling, and mechanical systems. The challenges of precision coil bending lie in achieving tight tolerances, maintaining structural integrity, and delivering consistent results, regardless of the complexity of the design.

Importance of Precision in Metalwork

Precision in coil bending is essential for industries such as:

- HVAC Systems: Coils are critical for heat exchangers and condensers.

- Petrochemical Plants: These facilities use intricately bent coils for efficient chemical processing.

- Medical Devices: High-precision coils ensure reliability in life-saving equipment.

Our Baton Rouge facility is equipped with state-of-the-art machinery and staffed by highly trained professionals, ensuring every project meets the stringent standards required by these industries.

Custom Metalwork in Baton Rouge: Meeting Unique Needs

Understanding Local Industrial Demands

Baton Rouge is home to a diverse industrial ecosystem. From petrochemical plants to emerging green energy companies, the city’s businesses often require custom solutions to maintain their competitive edge. Custom metalwork, especially precision coil bending, provides a tailored approach to solving unique engineering challenges. Whether it’s designing compact coils for limited spaces or creating robust components for high-pressure environments, our team delivers solutions built to last.

How We Tailor Solutions

Our approach to custom metalwork in Baton Rouge includes:

- Initial Consultation: Understanding the project’s requirements, constraints, and goals.

- Design Collaboration: Working with clients to create CAD designs that align with their specifications.

- Prototyping and Testing: Developing and rigorously testing prototypes to ensure quality and functionality.

- Production: Using advanced tools to produce precision coils at scale.

This end-to-end process ensures that our clients receive products that seamlessly integrate into their systems.

Advanced Tools and Techniques: A Competitive Edge

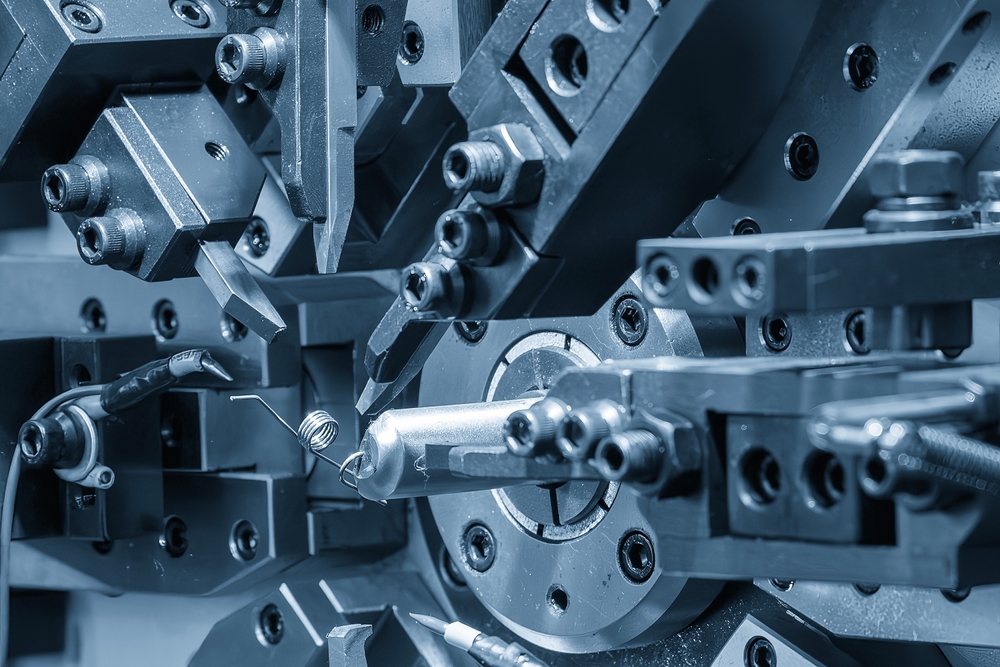

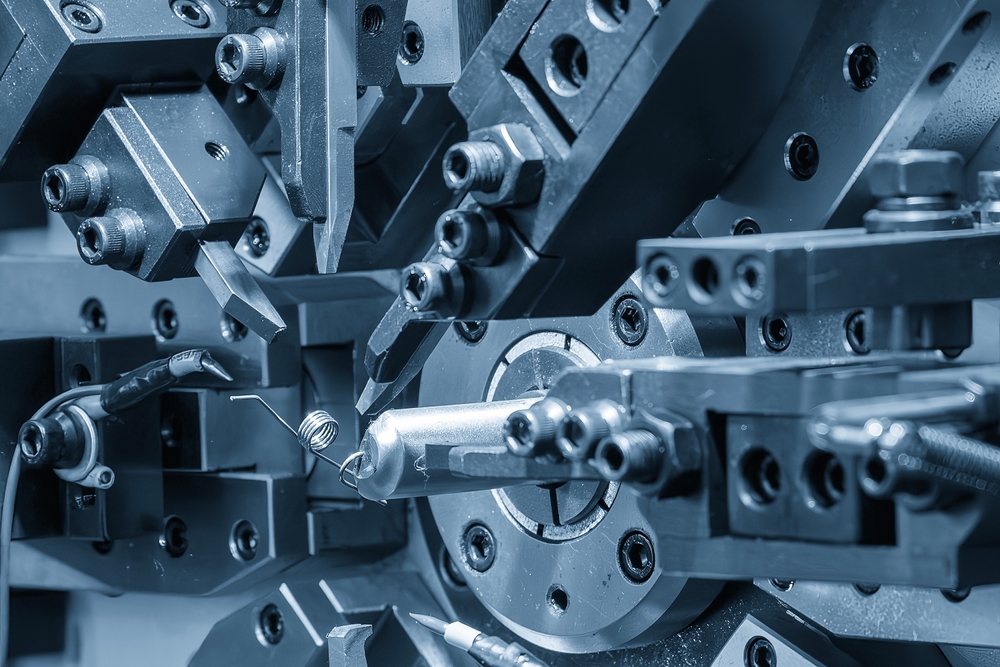

The ability to deliver precise, high-quality results comes from leveraging cutting-edge technology and innovative techniques. Our Baton Rouge facility is equipped with CNC (Computer Numerical Control) bending machines that provide unparalleled accuracy. Here’s how our tools set us apart:

CNC Bending Machines

CNC technology enables us to produce precision coil bending projects with:

- Consistent Accuracy: Automated systems ensure every coil matches exact specifications.

- Speed and Efficiency: High-volume production without sacrificing quality.

- Complex Designs: Capability to create intricate coil patterns that manual bending cannot achieve.

Material Expertise

We work with a variety of materials, including:

- Stainless Steel: Durable and corrosion-resistant, ideal for demanding environments.

- Copper: Excellent thermal conductivity for HVAC and refrigeration applications.

- Aluminum: Lightweight and versatile, perfect for aerospace and automotive industries.

Each material presents unique challenges, but our skilled technicians understand how to handle them effectively, ensuring optimal results for every project.

Why Baton Rouge Trusts Our Expertise

Proven Track Record

Over the years, we have built a reputation as a trusted provider of custom metalwork in Baton Rouge. Businesses across various sectors turn to us because of our consistent delivery of high-quality results. Our portfolio includes projects for leading companies in:

- Energy

- Healthcare

- Construction

- Manufacturing

Commitment to Excellence

We’re not just a service provider; we’re a partner in success. Our commitment to excellence is evident in our meticulous attention to detail, open communication, and dedication to meeting deadlines. Baton Rouge businesses know they can rely on us to go above and beyond to meet their needs.

Customer-Centric Approach

What sets us apart is our focus on building lasting relationships with our clients. From the initial consultation to post-delivery support, we prioritize transparency and collaboration. This approach ensures that every precision coil bending project exceeds expectations.

Applications of Precision Coil Bending

The versatility of precision coil bending means it is utilized across numerous industries in Baton Rouge. Here are some examples:

HVAC and Refrigeration

Custom coils are vital components in HVAC systems, enabling efficient heat exchange and temperature control. Whether for residential buildings, commercial spaces, or industrial facilities, precision coil bending ensures optimal performance.

Petrochemical and Refining

The petrochemical industry demands high-performance equipment capable of withstanding extreme temperatures and pressures. Precision coil bending enables the production of durable, efficient components for these challenging environments.

Medical and Laboratory Equipment

In the medical sector, precision is paramount. Coil bending is used to create components for diagnostic machines, surgical tools, and laboratory instruments, where even minor inaccuracies can have significant consequences.

Renewable Energy

Baton Rouge is seeing a growing focus on renewable energy solutions. Precision coil bending plays a role in creating efficient systems for solar power, wind turbines, and geothermal energy applications.

Environmental and Economic Benefits

Reducing Waste

Our precision coil bending process minimizes material waste, contributing to environmentally friendly practices. By optimizing designs and using advanced machinery, we ensure that every project is as efficient as possible.

Cost Savings

Precision in production reduces errors and rework, saving time and resources. Businesses in Baton Rouge benefit from cost-effective solutions without compromising on quality.

Training and Expertise: The Human Element

While advanced tools and machinery are essential, our team’s expertise is the cornerstone of our success. Each technician undergoes rigorous training to master the art of precision coil bending. This combination of human skill and technological innovation ensures that we deliver exceptional results every time.

Ongoing Education

To stay ahead in the industry, we invest in ongoing education for our team. This includes:

- Workshops and Seminars: Keeping up with the latest trends and techniques.

- Certifications: Ensuring compliance with industry standards.

- Collaboration with Experts: Learning from global leaders in precision coil bending and custom metalwork.

Need an Industrial Machine Shop in Baton Rouge, LA?

Established in 1956, our team here at Metal Works Corporation is an A.S.M.E. certified industrial fabrication company specializing in pipe and tube bending, pipe fabrication, coiling, vessel fabrication, and welding for major industries. Our in house’ machine shop has unique capabilities and produces specialty springs of all alloys, custom rotating mechanical seals, and various other industrial components. We appreciate our customers and work to forge lasting relationships built on trust and reliability. Contact us today and allow our team to be the shortest distance between problem and solution for your unique industrial requirements.