Metal springs have been a vital component in various mechanical systems for centuries, providing flexibility and elasticity to machinery and devices. The history of metal springs dates back to ancient civilizations, where they were first used in simple forms to assist in everyday tasks. In this blog post, we will explore the history of metal springs, their evolution, and their applications in modern times.

Metal Spring Production

The production of metal springs has evolved significantly over the years, starting from basic handmade techniques to sophisticated manufacturing processes. In the early days, metal springs were crafted by hand using simple tools and techniques. Blacksmiths and metalworkers would heat and shape metal rods into coils, creating the first primitive forms of springs. These basic springs were mainly used in small-scale applications, such as locks, traps, and clocks.

As technology advanced, new methods of metal spring production emerged, such as cold coiling and hot coiling. Cold coiling involves shaping metal wire into coils at room temperature using specialized machinery, while hot coiling involves heating the metal wire before coiling it to improve its flexibility and elasticity. These modern manufacturing processes have made it possible to produce metal springs in large quantities with consistent quality and precision.

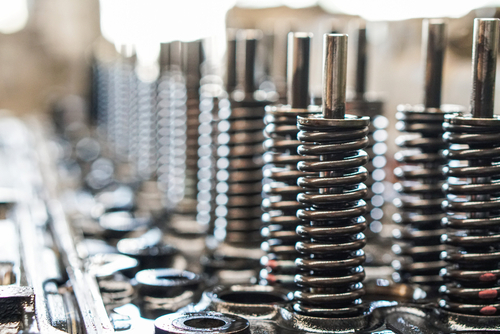

Coil Production

The invention of the coiling machine in the 19th century revolutionized the production of metal springs, enabling manufacturers to produce coils of various shapes and sizes with greater speed and accuracy. The coiling machine allowed for the mass production of metal springs, making them more affordable and accessible for a wide range of industries.

Coil production has since become a specialized field within the metalworking industry, with companies offering custom coil production services for a variety of applications. From compression springs to tension springs to torsion springs, metal coil production has become a versatile and essential manufacturing process for many industries, including automotive, aerospace, electronics, and more.

Metal Bending Services

In addition to coil production, metal bending services play a crucial role in the manufacturing of metal springs. Metal bending involves shaping metal rods or wire into curved or angled shapes to create the desired spring design. Metal bending services use specialized machinery, such as press brakes and roll bending machines, to precisely shape metal parts according to the specified dimensions and tolerances.

Metal bending services are essential for creating custom springs with unique shapes and configurations to suit specific applications. From leaf springs to flat springs to zig-zag springs, metal bending services can produce a wide range of spring designs for various industries and purposes. By utilizing metal bending services, manufacturers can create springs that meet the exact requirements of their applications, ensuring optimal performance and durability.

The Evolution of Metal Springs

Over the years, metal springs have undergone significant advancements in design, materials, and applications. From the simple coiled springs of ancient times to the sophisticated springs used in modern machinery, the evolution of metal springs has been driven by technological innovation and industry demands. Advances in materials science have led to the development of high-performance spring materials, such as stainless steel, titanium, and nickel alloys, that offer superior strength, corrosion resistance, and durability.

Today, metal springs are used in a wide range of industries and applications, from automotive and aerospace to medical devices and consumer electronics. Springs play a critical role in machinery and equipment, providing essential functions such as shock absorption, vibration isolation, tension, compression, and torsion. Whether it’s a car suspension system, a door hinge, a watch movement, or a medical implant, metal springs are indispensable components that keep things moving smoothly and reliably.

Summary

The history of metal springs is a fascinating journey that spans centuries of innovation and ingenuity. From their humble beginnings in ancient times to their diverse applications in modern times, metal springs have become indispensable components in countless mechanical systems and devices. With advancements in manufacturing processes, coil production, and metal bending services, the future of metal springs is bright, with endless possibilities for new designs and applications to meet the evolving needs of industry and technology.